Time: 2025-10-16

Time: 2025-10-16  Views: 315

Views: 315

[Foreword]

Decision has been deeply involved in the SAP field for more than 19 years and has been praised by many customers. In order to better help customers implement digital projects, the "Decision Expert Column" is completely free and open source, paying tribute to Musk's open source spirit!

Based on the senior capabilities of Decision's expert consultant team with more than 20 years of SAP experience, combined with Decision's 1,000+ successful project cases, this article summarizes and publishes the corresponding research experience and suggestions of enterprises in promoting ERP project implementation, and continues to escort the SAP implementation and delivery of enterprises.

[Problem description]

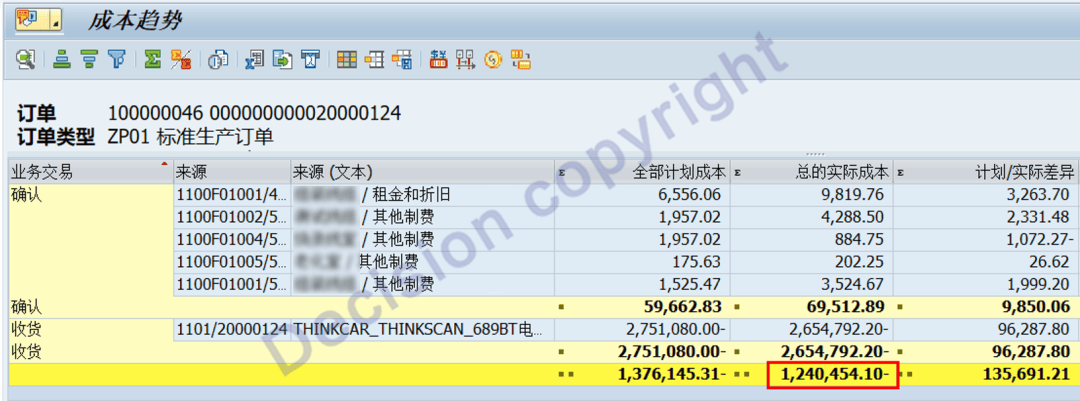

Factory 1101, production order 100000046 for semi-finished product 20000124. The planned production volume for January was 2000 pieces, and 1930 pieces were received in January (95% completion, 5% work-in-progress). The actual cost of semi-finished product 20000124 is typically between 600 and 700 yuan per piece. However, due to an error in the standard cost release, the standard cost was 1,375.54 yuan per piece. All 1930 pieces were received in January at the standard cost of 1,375.54 yuan per piece, resulting in a production order cost balance of -1,240,454.10 yuan at the end of January. In the S4 system, production order cost variances are allocated between finished goods and work-in-progress. Why isn't this "-1,240,454.10 yuan" allocated between the 1930 pieces received and the 70 pieces of work-in-progress?

[Problem Analysis]

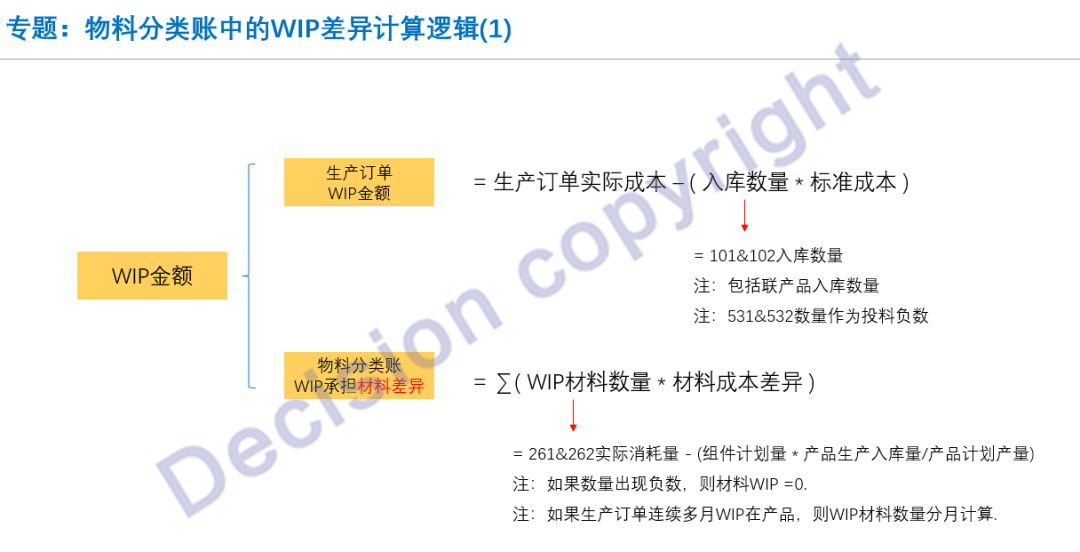

1. First, the work order variance amount is allocated between the work in progress and the finished product. This means that the price difference of the raw materials and semi-finished products consumed in the production work order is allocated to the work in progress and the finished product when it is transferred to the work order product. The allocation relationship is as follows:

2. The "-1,240,454.10 yuan" in the production order refers to the remaining cost of the production order, but the cost balance here is negative!

The remaining cost of a production order is not allocated between work-in-progress and finished goods!

This is because if the input is posted too low, it's uncertain how much work-in-progress will be produced.

The S4 system simply allocates the price difference of 261/0.262 for material input in production order 100000046 based on the quantity relationship.

3. Analyze the standard cost of semi-finished product 20000124. Why is it published incorrectly?

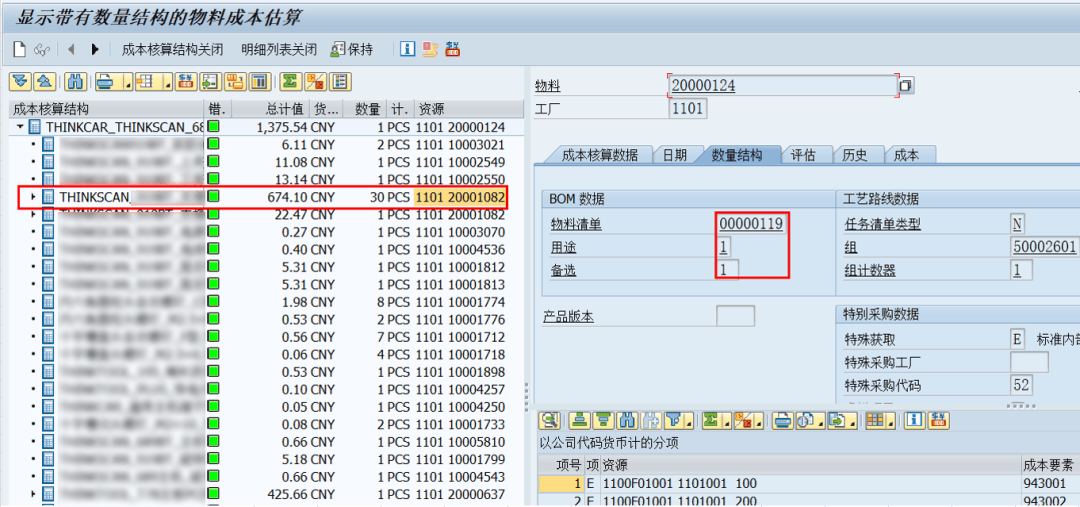

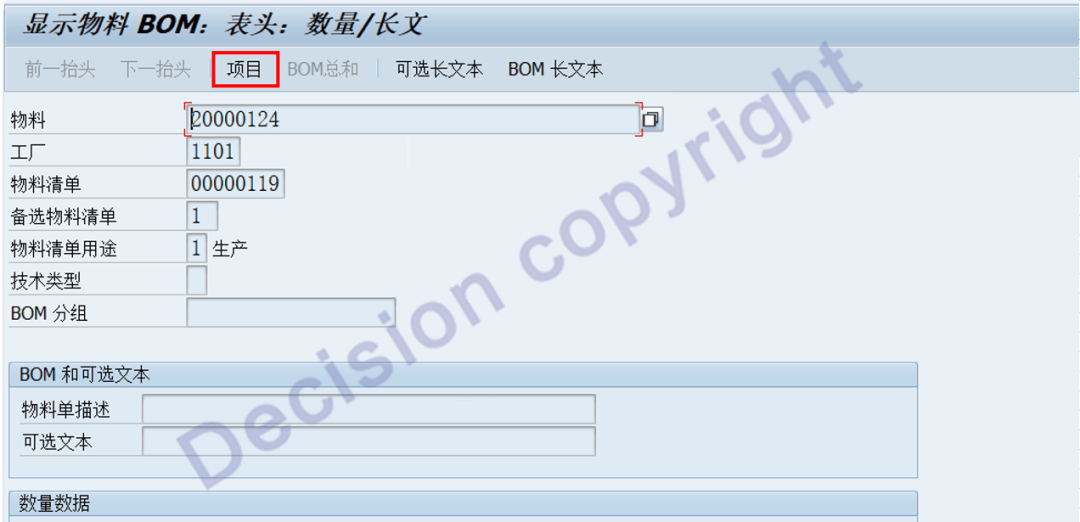

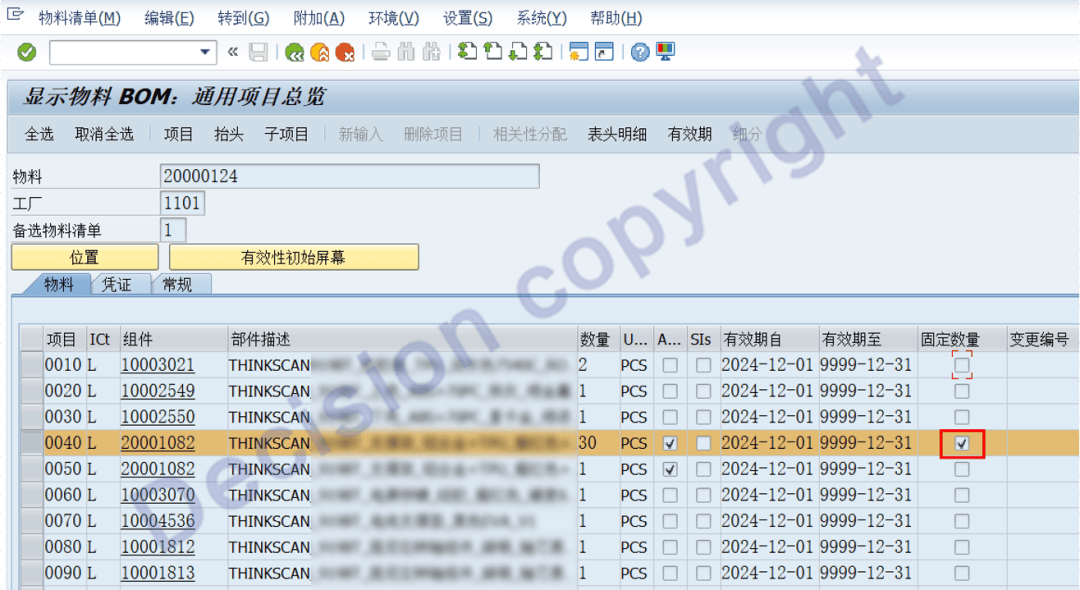

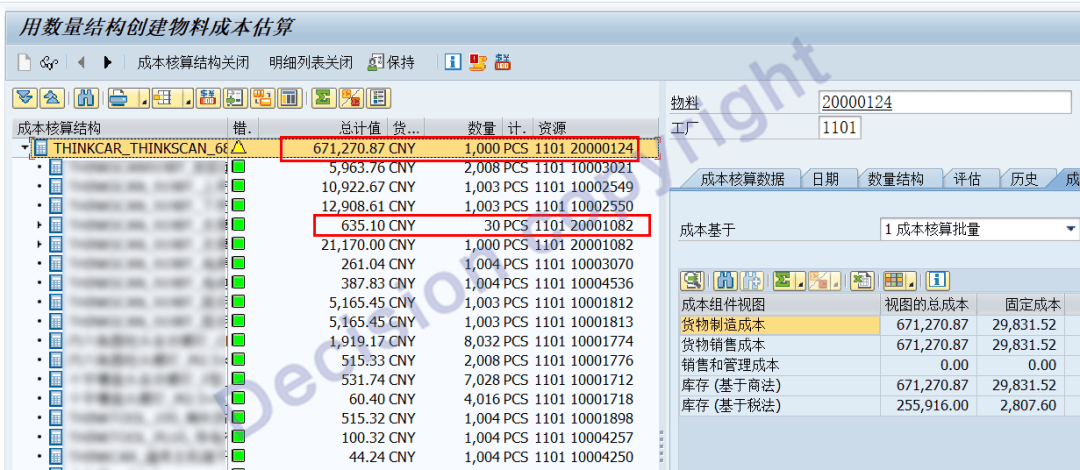

Using transaction code CK13N, the published standard cost shows that 1 PC computer requires 30 units of support, costing 674.10 yuan. Double-click the BOM number for the standard cost.

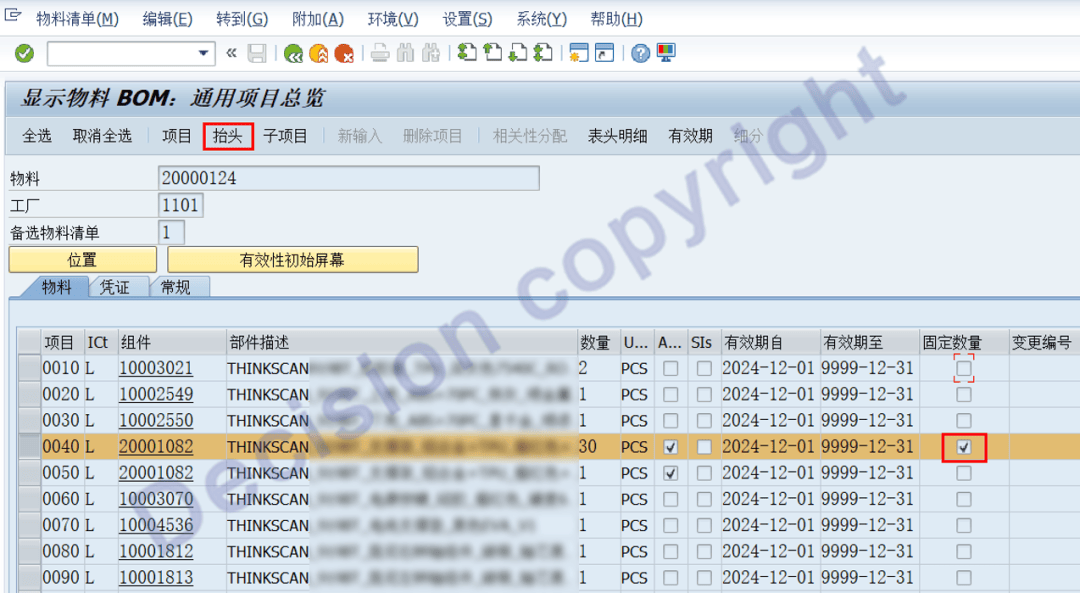

It can be seen that the subordinate material: 20001082 consumes 30 PC, which is a fixed consumption. Continue to check the header base quantity.

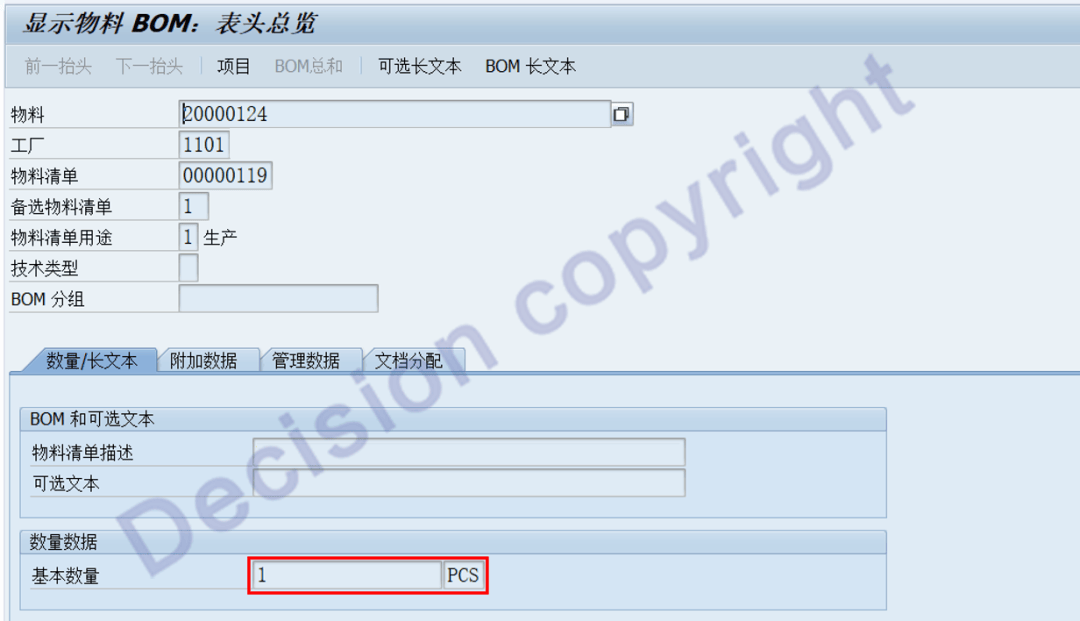

Here we see that the basic quantity is 1 PC. Generally, a fixed consumption of 30 PCs is for an economic production batch, such as 1,000 or 2,000 units.

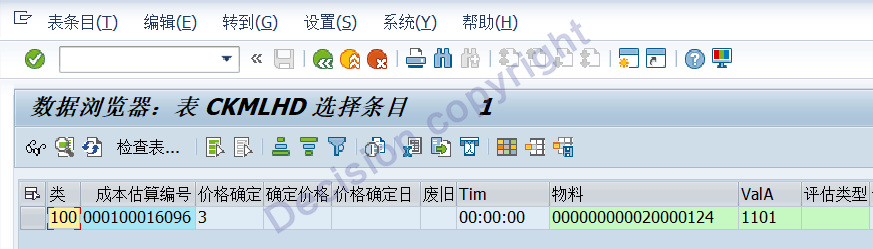

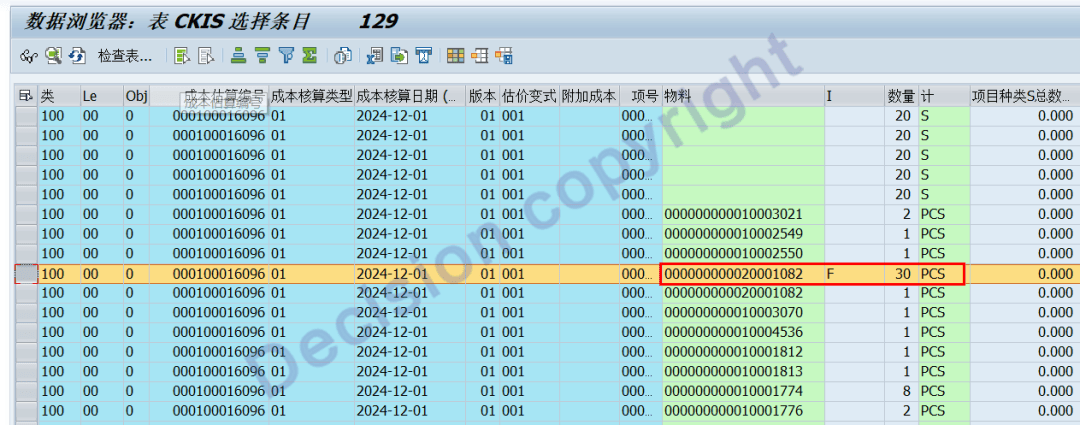

5. View factory 1101, semi-finished product 20000124 estimate number:

6. Checking the standard cost release details of the cost estimate number, we can see that the fixed consumption of the BOM was read when the standard cost was calculated in January, but the economic batch was not maintained in time, resulting in an incorrect standard cost!

7. In summary, the problem of inaccurate standard costs stems from failures in the following three lines of defense.

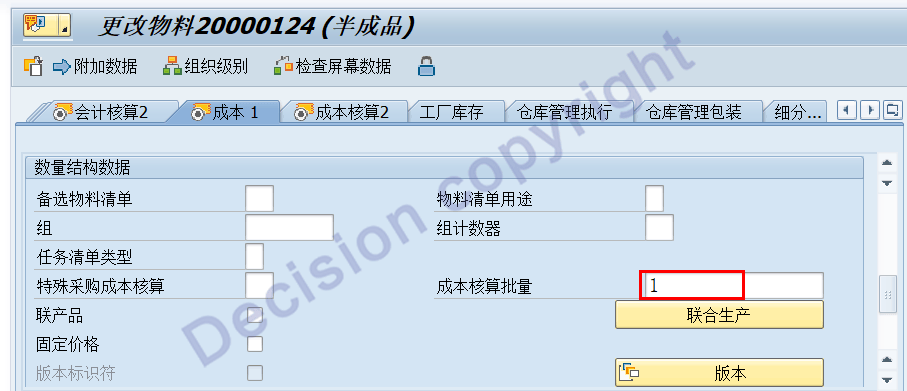

1) In the PP module BOM, the corresponding fixed consumption was maintained, but the corresponding production economic batch size was not.

2) When calculating and publishing standard costs in the CO module, the costing batch size was not considered, and the standard costing batch size defaulted to 1.

3) After the CO module calculated standard costs, they were not carefully checked before publishing. A product's actual cost was 600-700 yuan, but the published standard cost was 1,375.54 yuan, and this was not promptly checked.

[Solution]

1. Standard costs must be updated promptly.

Use transaction code MM02 to change the costing batch size in the Cost 1 view to the economic batch size.

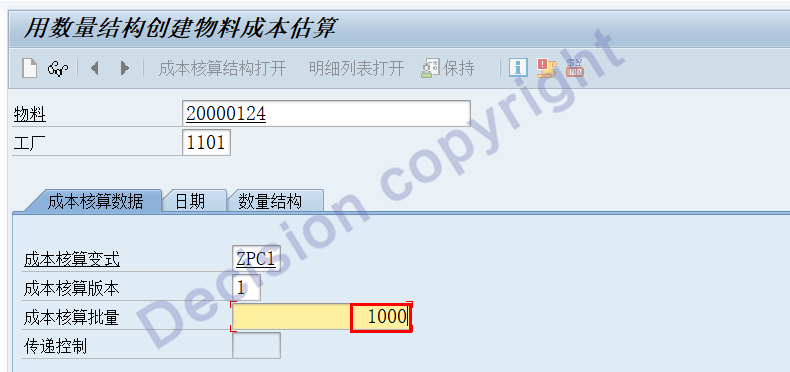

When calculating standard cost using transaction code CK11N, enter the economic batch size (either through material master data or the CK11N screen).

After recalculation, the standard cost = 671,270.87 yuan/1000 PCs = 671.27 yuan/1 PC.

2. For production orders with large standard cost deviations, high completion rates, and low work-in-process rates, close the production order early with a TECO for settlement purposes, perform a January completion settlement, and cancel the TECO after settlement.

1) Perform a technical close on production order 100000046 using transaction code CO02.

2) Modify the technical close date for production order 100000046 using AUFK-IDAT2 (generally, this is done as a CO auxiliary tool).

3) Recalculate the work-in-process, calculate variances, re-settlement, and rerun the material ledger.

4) After the monthly close, cancel the technical close on production order 100000046 using transaction code CO02.

【Service Guide】

For more information on SAP courses, project consultation and operation and maintenance, please call Decision's official consultation hotline: 400-600-8756

【About Decision】

Global professional consulting, technology and training service provider, SAP gold partner, SAP software partner, SAP implementation partner, SAP official authorized training center. Nineteen years of quality, trustworthy!